Productos

Segunda mano

Press Brake Die Seat: setup, tolerances and maintenance

Improve bend consistency by aligning, cleaning and inspecting the die seat before each run.

This guide details verification of flatness and parallelism, seating practices, and how to document tolerances for repeatable results.

- Less scrap and faster setups

- Safety and traceability

- Checklist for audits

Recommended reading

Review base tolerances and specs before adjusting tooling.

Suppliers of Manufacturing and Grinding Dies for Sheet Metal Bending Machines

Verifica procesos, tolerancias y tiempos de entrega antes de ordenar.

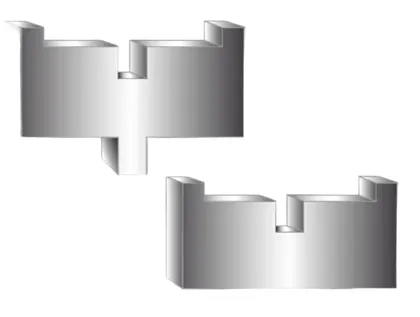

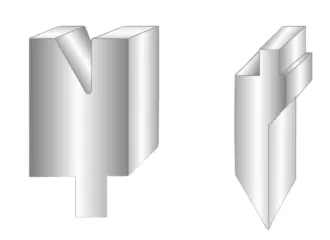

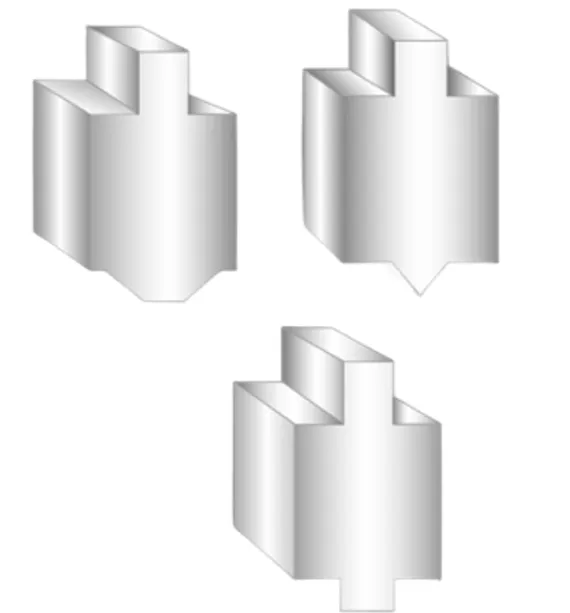

Die seat fundamentals and impact on bend quality

The die seat is the reference surface where the lower die rests. If it is not clean, flat and parallel to the ram travel, the bend angle will vary along the length, causing rework and tool wear.

| Variable | Risk if out-of-spec | Control |

|---|---|---|

| Seat flatness | High spots, angle drift | Scrape/light lap; verify with straightedge + feeler |

| Parallelism bed–ram | Different angles L–C–R | Indicator sweep; compensate with shims/crowning |

| Cleanliness | False readings, galling | Wipe, solvent, debris removal |

Record zero reference and adjustments for each material/lot.

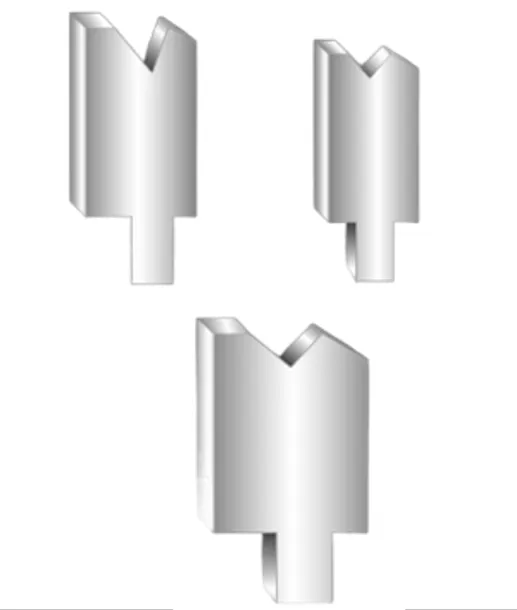

Seating and alignment procedure

- Clean the seat and tool contact surfaces.

- Place the die and snug clamps in a cross pattern.

- Sweep with a dial indicator along the length; aim for ≤ 0.05–0.10 mm variation.

- Shim if needed; verify punch–V centering.

- Tighten to torque specifications and re-check.

Finish with a sample coupon and record L–C–R angles.

Recommended tolerances and how to verify

| Item | Typical tolerance | Verification |

|---|---|---|

| End-to-end level | ≤ 0.05–0.10 mm | Dial indicator sweep |

| Punch–V centering | ≤ 0.10 mm | Gauges/calipers |

| Angle variation (L–C–R) | ≤ ±0.5° | Protractor or angle meter |

Adjust crowning/compensation depending on thickness and strength.

Preventive maintenance: frequencies and records

- Daily: quick cleaning and visual check

- Weekly: fastener torque and parallel check

- Monthly: full dimensional inspection

Minimum records

- Date, shift and responsible

- Tool ID and location

- Actions and findings

- Next intervention