Preventive maintenance, safety and traceability

Suggested routines

- Daily: light cleaning and visual check.

- Weekly: parallelism and torque verification.

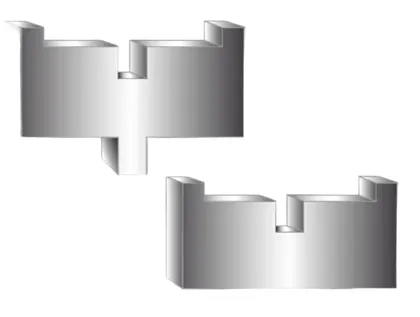

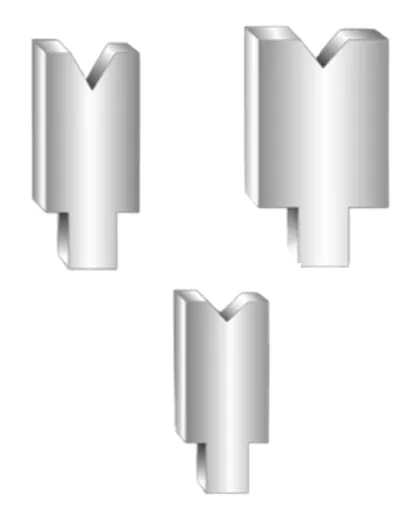

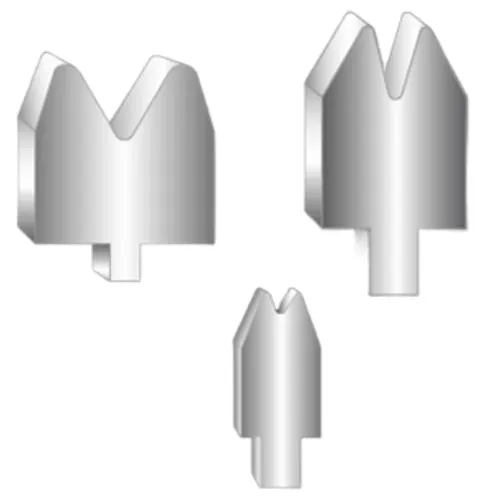

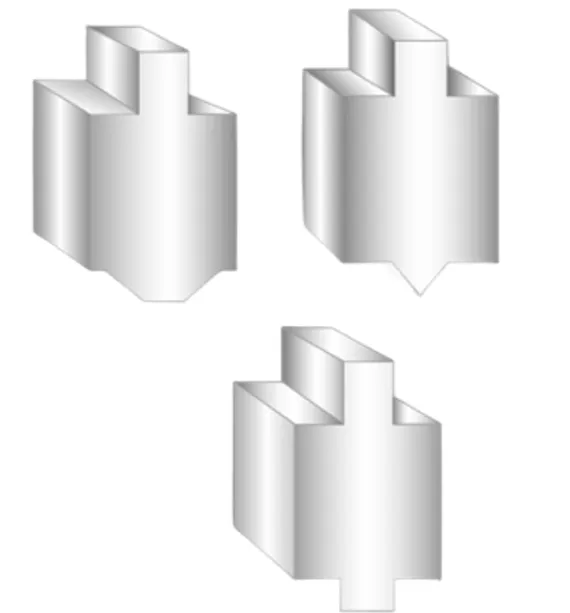

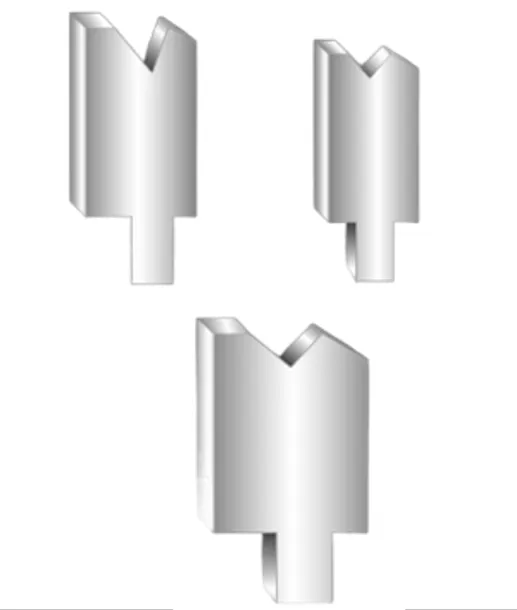

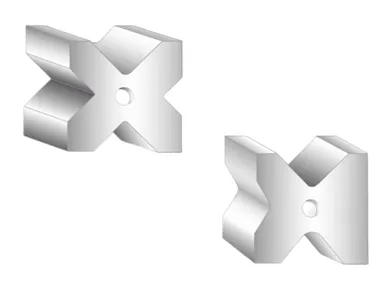

- Monthly: dimensional inspection of seat/blocks.

Avoid excessive lubricant that traps debris and alters effective height.

Minimum logbook

| Date | Machine | Die P/N | Activity | Δ L–C–R | Owner |

|---|---|---|---|---|---|

| __/__/__ | PB-### | XXXX | Torque/Clean | ±0.3° | Op. |

| __/__/__ | PB-### | XXXX | Inspection | ±0.4° | Tech |

Safety: LOTO during interventions, cut-resistant gloves and face shield; never hammer to “seat” the assembly.